Enhancing Environmental Monitoring in Pharmaceutical GMP Environments

Implementing improvements to environmental monitoring graphics is a straightforward way to enhance quality of life in the plant, offering time saving benefits.

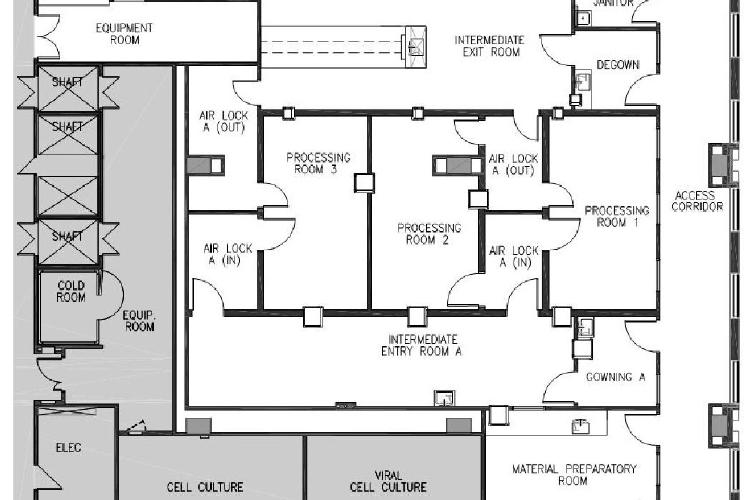

In this article, we will explore the best way to implement operator graphics for environmental monitoring in a pharmaceutical GMP environment using the DeltaV system, with a focus on utilizing floorplan CAD files as a base graphic to enhance the user experience and provide employees with an informative map-like interface.

The Role of Operator Graphics in Environmental Monitoring

Operator graphics play a vital role in facilitating effective and intuitive monitoring and control of complex systems. In a pharmaceutical GMP environment, operators need quick access to critical information such as temperature, humidity, pressure differentials, and other key parameters relevant to maintaining a controlled environment. By leveraging operator graphics, operators can easily visualize the monitored areas and promptly identify any deviations or alarms, enabling timely intervention to mitigate risks and maintain product quality.

Utilizing Floorplan CAD Files as Base Graphics

One of the most effective ways to implement operator graphics for environmental monitoring is by utilizing floorplan CAD files as a base graphic. The floorplan serves as a blueprint of the facility, providing a familiar and easily understandable representation of the physical layout. Integrating this CAD file into the DeltaV system allows operators to view and interact with the environment as a digital map, enhancing situational awareness and simplifying navigation.

Two Levels of Graphics

To further enhance the user experience, it is beneficial to incorporate two levels of graphics in the operator interface. The first level provides an overview of the entire facility, displaying the larger floor plan. Operators can click on specific sections or areas of interest to zoom in and access the second level of graphics, which provides a more detailed view of that particular section. This zooming capability enables operators to focus on specific areas, equipment, or rooms with greater precision, facilitating a comprehensive understanding of the environment and enabling efficient monitoring and control.

Benefits of Using Floorplan CAD Files as Base Graphics

-

Familiarity and Context: Floorplan CAD files provide operators with a familiar representation of the facility. By incorporating this base graphic into the operator interface, operators can easily identify and locate specific areas, equipment, or rooms within the GMP environment. This contextual understanding aids in faster decision-making and troubleshooting.

-

Spatial Awareness: The floorplan-based operator graphics enable operators to visualize the relationships between different monitored areas, equipment, and environmental parameters. Operators can quickly identify proximity, adjacency, and potential impact of deviations, making it easier to assess the overall environmental conditions and respond accordingly.

-

Tag Placement and Navigation: By overlaying tags representing various monitored parameters onto the floorplan graphic, operators can easily locate and interpret specific measurements. Whether it’s temperature sensors, pressure gauges, or air quality monitors, the tags act as informative markers, allowing operators to quickly identify abnormal readings and take appropriate actions. Additionally, operators can navigate through the floorplan interface to access detailed information or make adjustments as needed.

-

Time-Saving Troubleshooting and Maintenance: Floorplan-based operator graphics significantly streamline troubleshooting and maintenance activities for the maintenance staff. By accurately placing tags representing sensors and devices on the floorplan graphic, maintenance personnel can quickly identify the exact locations of equipment and environmental sensors. This knowledge eliminates the need for time-consuming searches or manual inspections, enabling them to promptly address issues and perform repairs with precision. The floorplan-based interface serves as a valuable tool for efficient maintenance management, ensuring minimal downtime and maximizing operational efficiency.

Conclusion

Efficient and accurate environmental monitoring is indispensable in pharmaceutical GMP environments. By implementing operator graphics using floorplan CAD files as base graphics within the DeltaV system, pharmaceutical manufacturers can enhance their monitoring capabilities, improve operator situational awareness, and facilitate swift response to deviations and alarms. The floorplan-based interface not only provides familiarity and context but also allows for intuitive tag placement and navigation, resulting in optimized environmental control and compliance. A simple and easy thing to implement in a codebase at any time that improves quality of life at a plant for everyone.